Ginger

In 2014 Europe imported 72.000 mt Ginger, Germany 15.000 mt thereof. The biggest producer of Ginger is India with 250.000 mt, the biggest fields are in Nigeria and the biggest exporter is China! Asia is producing 89 % of Ginger, the rest is out of Africa. The question is: is Africa likely to catch up?!

Ginger Cooperative

We are visiting a Ginger cooperation in Same, in the North of Tansania. 80 % of the tansanian ginger is produced here, the rest is harvested in Songea/Ruwuma in the South of Tanzania.

The Ginger Area in Same is situated on top of inaccessible mountainous regions. Our small busses agonize uphill: in fact they need nearly 4 hours for a bad road of 60 km – up to the mountains.

We were rewarded with a wonderful of the valley with lots of beautiful Ginger Terraces.

Ginger is grown as a monoculture. It is a biennale plant, which need a lot of water. Therefore Ginger is planted in small basins, which are situated in small terraces at the mountain slopes.

Elsewhere valleys are used, for an adequate irrigation.

Planting is easy: just take some root sections (sets), put them into the earth and wait until they have formed their own roots. The farmers in Same plant Ginger together with Corn, to have yearly crops. Season is from July to September

Meetings

TAFAPDA (Tanzania Farmers Productivity and Development Association) supported our cooperative of Ginger Farmers and Processors. They gave the money for a new productions building, a new warehouse and some new machines.

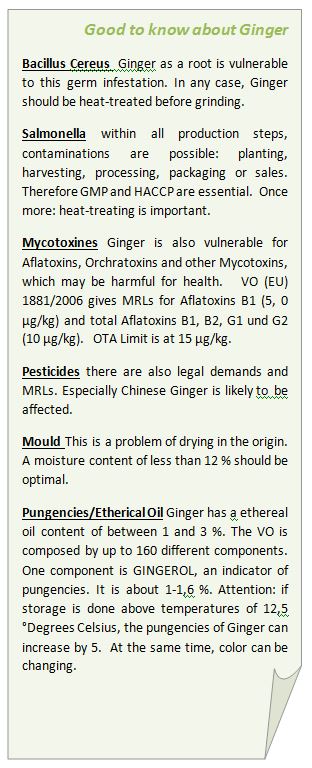

The Warehouse is a meeting point and we had a meeting with the farmers there. Easy to summarize: the farmers had no idea about Salmonella, Mycotoxins or Bacillus Cereus.

Potentials

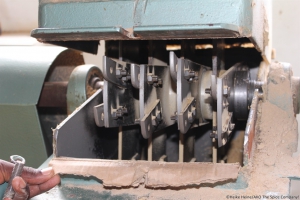

By means of TAFAPDA (Tanzania Farmers Productivity and Development Association) the cooperation has perfect machinery equipment

Those of us who have experiences in quality management, realized some rat excrements in the dryer table. The roof in production was damaged, birds were in the building. Machineries – although season was finished since September – were dirty and not clean. We also found rubbish in the drying room and non-sealed bags in the warehouse.

Development Aid run out – and now?

The Ginger Cooperative has got good equipment via the development aid. But those resources had not been utilized in full capacity and equipments had not been maintained and serviced. The cooperation is selling mostly fresh ginger (more than 80 %), whereas the European Spice Industry requires dried Ginger (sliced or grinded) due to high risk of mould.

The Ginger cooperative harvests 7.000 mt p/year. 95 % are sold to Kenia and India as fresh Ginger. If the production will not be increased, there will not be sufficient goods to export to Europe.

Equipment and facilities were in poor condition: after the phase out of development aid project, all donations are rotting.

However this is a general problem of a country: obtaining development assistant. As soon as those projects are finished – people are left alone with their problems. A fatal mistake: because a sensitive product like Ginger can only be produced in a secure way, if the processing unit cares on hygiene and product safety.

In any case a steam-treating facility is missing to reduce the risk – if it is not available in the Origin it should be at least provided in the importing countries.

All information are based on our own experiences and opinion. We do not assume any liabilities for completeness or correctness.